| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Zhongdong

Model Number : KVVP NYCY

Certification : ISO,VDE,ISO,TUV

Place of Origin : Hebei,China

MOQ : Negotiable

Price : Negotiable

Payment Terms : L/C,T/T

Supply Ability : 100KM/Week

Delivery Time : 10Work days

Packaging Details : Wooden Steel Drums

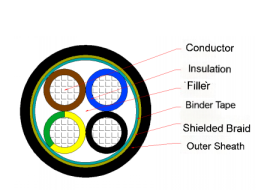

Conductor Material : Copper

Insulation Material : PVC

Application : Industrial

Jacket : PVC

Color : Optional

cores : 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Copper braid shielded cables are widely used in industries that require reliable signal transmission, noise immunity, and electromagnetic interference (EMI) protection. Below are key applications:

1. Industrial Automation & Control Systems

Used in PLC (Programmable Logic Controller) systems, motor control circuits, and industrial machinery.

Ensures stable transmission of control signals in harsh environments (e.g., factories, power plants).

2. Instrumentation & Measurement Systems

Deployed in sensors, transmitters, and data acquisition systems where precision is critical.

Shields against external noise, ensuring accurate signal integrity.

3. Power & Energy Sector

Applied in substations, switchgear, and renewable energy systems (solar/wind farms).

Protects against EMI from high-voltage equipment.

4. Communication & Networking

Used in shielded Ethernet cables (e.g., Cat6A SF/UTP) for high-speed data transmission.

Ensures signal clarity in industrial Ethernet (PROFINET, Modbus, etc.).

5. Transportation & Automotive

Employed in railway signaling, electric vehicle (EV) charging stations, and automotive CAN bus systems.

Reduces electromagnetic noise from high-power components.

6. Medical & Aerospace

Critical in medical imaging (MRI, CT scanners) where EMI must be minimized.

Used in avionics and satellite communication systems for high-reliability transmission.

GB/T9330-2020

| Specs | Conductor diameter | Nominal thickness of insulation | Nominal thickness of sheath | Approximate outer diameter of cable | Approximate cable weight |

| 2×0.5 | 0.92 | 0.6 | 1.2 | 7.7 | 78.2 |

| 2×0.75 | 1.13 | 0.6 | 1.2 | 8.2 | 88.7 |

| 2×1 | 1.30 | 0.6 | 1.2 | 8.5 | 98.1 |

| 2×1.5 | 1.60 | 0.7 | 1.2 | 9.5 | 123.7 |

| 2×2.5 | 2.02 | 0.8 | 1.2 | 10.8 | 163.2 |

| 2×4 | 2.59 | 0.8 | 1.2 | 11.9 | 209.0 |

| 2×6 | 3.17 | 0.8 | 1.5 | 13.7 | 283.3 |

| 2×10 | 4.10 | 1.0 | 1.5 | 17.4 | 449.3 |

| 3×0.5 | 0.92 | 0.6 | 1.2 | 8.1 | 90.4 |

| 3×0.75 | 1.13 | 0.6 | 1.2 | 8.5 | 104.0 |

| 3×1 | 1.30 | 0.6 | 1.2 | 8.9 | 116.4 |

| 3×1.5 | 1.60 | 0.7 | 1.2 | 10.0 | 149.4 |

| 3×2.5 | 2.02 | 0.8 | 1.2 | 11.4 | 202.0 |

| 3×4 | 2.59 | 0.8 | 1.2 | 12.6 | 264.1 |

| 3×6 | 3.17 | 0.8 | 1.5 | 14.7 | 376.2 |

| 3×10 | 4.10 | 1.0 | 1.5 | 18.5 | 577.4 |

| 4×0.5 | 0.92 | 0.6 | 1.2 | 8.7 | 105.5 |

| 4×0.75 | 1.13 | 0.6 | 1.2 | 9.2 | 122.5 |

| 4×1 | 1.30 | 0.6 | 1.2 | 9.6 | 138.3 |

| 4×1.5 | 1.60 | 0.7 | 1.2 | 10.8 | 179.7 |

| 4×2.5 | 2.02 | 0.8 | 1.2 | 12.3 | 246.4 |

| 4×4 | 2.59 | 0.8 | 1.5 | 14.5 | 361.3 |

| 4×6 | 3.17 | 0.8 | 1.5 | 15.9 | 463.9 |

| 4×10 | 4.10 | 1.0 | 1.5 | 20.2 | 719.9 |

| 5×0.5 | 0.92 | 0.6 | 1.2 | 9.3 | 121.3 |

| 5×0.75 | 1.13 | 0.6 | 1.2 | 9.8 | 142.0 |

| 5×1 | 1.30 | 0.6 | 1.2 | 10.3 | 161.0 |

| 5×1.5 | 1.60 | 0.7 | 1.2 | 11.7 | 211.2 |

| 5×2.5 | 2.02 | 0.8 | 1.5 | 14.0 | 311.8 |

| 5×4 | 2.59 | 0.8 | 1.5 | 15.7 | 428.8 |

| 5×6 | 3.17 | 0.8 | 1.5 | 17.3 | 554.6 |

| 5×10 | 4.10 | 1.0 | 1.7 | 22.4 | 888.1 |

| 7×0.5 | 0.92 | 0.6 | 1.2 | 9.9 | 143.1 |

| 7×0.75 | 1.13 | 0.6 | 1.2 | 10.5 | 169.6 |

| 7×1 | 1.30 | 0.6 | 1.2 | 11.1 | 194.2 |

| 7×1.5 | 1.60 | 0.7 | 1.2 | 12.6 | 257.9 |

| 7×25 | 2.02 | 0.8 | 1.5 | 15.3 | 400.3 |

| 7×4 | 2.59 | 0.8 | 1.5 | 17.0 | 533.4 |

Q: What is a copper braid shielded cable?

A: A copper braid shielded cable features a woven copper mesh layer around conductors to block electromagnetic interference (EMI) and radio frequency interference (RFI).

Q: Why is copper braid shielding preferred over foil shielding?

A: Copper braid offers higher flexibility, better mechanical durability, and superior grounding performance compared to aluminum foil.

Q: In which industries are copper braid shielded cables essential?

A: Critical in industrial automation, medical equipment, aerospace, and high-speed data transmission systems where EMI protection is vital.

Q:What standards govern copper braid shielded cables?

A:Compliant with EN 50525 (Europe), UL 2250 (North America), and IEC 60502 (international).

Q: How does copper braid shielding improve signal integrity?

A: It minimizes noise distortion by absorbing and redirecting external electromagnetic waves, ensuring clean signal transmission.

Q: What’s the temperature rating of copper braid shielded cables?

A: Typically rated for -40°C to +90°C (Europe) or -40°C to +75°C (UL standards).

Q: Can copper braid shielded cables be used in wet environments?

A: Yes, with proper insulation (e.g., PVC or LSZH jackets) to resist moisture and chemicals.

Q: How is shielding effectiveness measured?

A: Attenuation (dB) is tested per EN 50288 or MIL-STD-220A, with 70-90dB common for industrial cables.

Q: Are copper braid cables suitable for high-frequency applications?

A: Yes, their low resistance and high conductivity make them ideal for RF, Ethernet, and telecom signals up to 10 GHz.

|

|

450/750V Copper Conductor Control Cable PVC Insulation PVC Sheath Braided Shielded Cable Images |